Chem-Trend® Spray Foam Remover Mold Cleaner – 5 Gallons

Chemlease® products for composites molding offer extreme value through their combination of advanced technology, ease of application, and positive impact on operational efficiency. A variety of products have been developed to work together as a release system, addressing the wide range of composites molding applications and challenges. Many are available in water-based formulations to allow for a more environmentally conscious and regulatory-compliant approach. Chemlease® mold cleaners are designed to keep molds and tools in peak condition. SDS TDS

Chem-Trend® SprayFoam Release

Chem-Trend® SprayFoam Release is a blend of silicones and specialized parting agents that are specifically designed to prevent spray polyurethane foam insulation from adhering to most surfaces where the product is applied. Chem-Trend® SprayFoam Release acts as an effective barrier coat to keep overspray of polyurethane foam insulation from adhering to items such as spray equipment, tub & shower stalls and other non-porous surfaces. Chem-Trend® SprayFoam Release should not be applied to personal protective equipment. SDS

Select options This product has multiple variants. The options may be chosen on the product page

Closed Cell Vinyl Foam Tape – Gray

- Wide Gap Closed-Cell Vinyl Foam Tape

- Waterproof and weather-resistant.

- Self-adhesive, just peel and press.

- Light gray in color

Select options This product has multiple variants. The options may be chosen on the product page

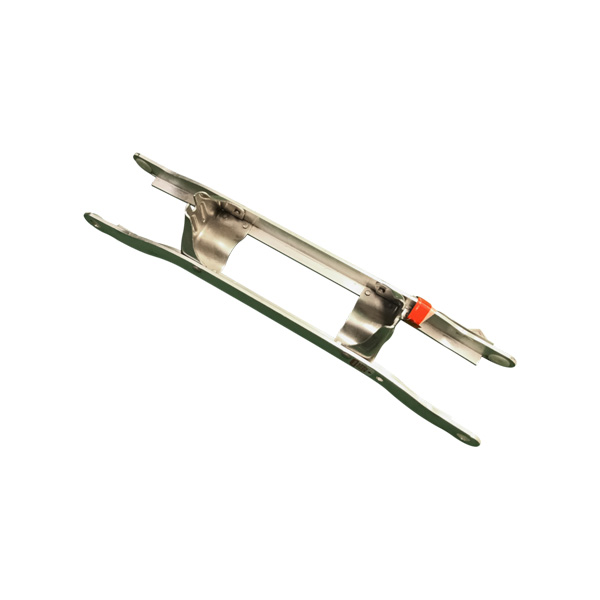

Curry Comb Set 4″ & 5″

CURRY COMB FOAM SCRAPERS(2 comb set) 1- 4" and 1-5" With Reversible Heads. Reversible Curry Combs are assembled with non-rusting spacers and riveted together for an attractive durable comb. A tension spring snugs the comb firmly on the bright metal shank pin to permanently attach the Grip-Fit polypropylene handle to the comb The shank pin allows the comb to reverse easily on the handle. The finished combs are lacquer dipped to give them a bright durable finish. They are sold in sets of 2 to take advantage of better shipping rates and can be combined with other tools for further shipping discounts. Pricing is per set quantity.

DC-315 Thermal Barrier Coating

The International Building Code mandates that polyurethane spray foam be separated from the interior of the building by a 15-minute thermal barrier or other approved covering. DC315 passed certified NFPA 286 and UL 1715 by ETL over a variety of open and closed cell spray-applied urethane foams. It complies with all the requirements of 2006 IBC Section 803.2.1; 2009 IBC Section 803.1.2 and Section 2603.9; 2012 IBC Section 803.1.2 and Section 2603.10 "Special Approvals for Thermal Barriers over Foam Plastics". DC315 also meets the requirement as an Ignition Barrier per AC 377, Appendix X at an incredible spread rate of 400 sq. ft. per gallon.

Characteristics- Finish: Flat

- V.O.C.: (47 g/l)

- Volume Solids: 67%

- Drying Time: 77F & 50% RH To touch 1-2 hours to recoat 2 to 4 hours

- Type of Cure: Coalescence

- Flash Point: None

- Reducer/Cleaner: Water

- Shelf Life: 1 year (unopened)

- Packaging: 5 gallon pail

- Shipping weight: 5 gallon pail - 58 lbs

- Application: Brush, roller, conventional and airless spray

Select options This product has multiple variants. The options may be chosen on the product page